calcium carbonate loading plastic bottle manufacturing tests|calcium carbonate feeders : manufacture Among these, calcium carbonate (both natural and synthetic) is the most abundant and affords the possibility of improved surface finishing, control over the .

Como saber se o Copo Stanley é original ou falsificado? Logotipo e Marcação. Verifique se o logotipo da Stanley está claramente impresso no copo. As falsificações podem ter um logotipo mal impresso ou ausente. Qualidade do Material. Copos originais da Stanley são feitos com materiais de alta qualidade, como aço inoxidável.

{plog:ftitle_list}

Resultado da 11 de jan. de 2024 · Salve agora essa imagem do topo de bolo: Topo de Bolo Poderoso Chefinho PNG Dicas Para Usar o Topo. Após salvar seu topo de bolo é preciso usar papel fotográfico 230g para imprimir, pois assim seu topo de bolo vai ficar completo na hora da impressão. Após imprimir .

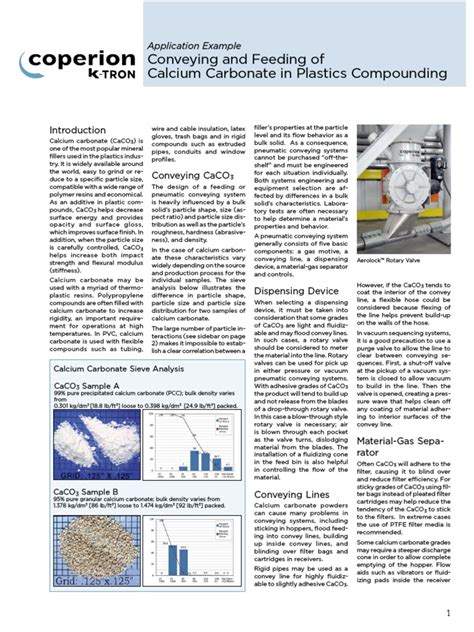

Calcium carbonate (CaCO3) is one of the most popular mineral fillers used in the plastics indus-try. It is widely available around the world, easy to grind or re-duce to a specific particle size, compatible with a wide range of polymer resins and economical. Fibrous materials, particularly when properly coupled to the polymer, provide true reinforcing qualities that offer a higher strength-to-weight ratio than a particulate like talc or .Calcium carbonate (CaCO 3) is one of the most popular mineral fillers used in the plastics industry. It is widely available around the world, easy to grind or reduce to a specific particle .Many polyolefin applications have successfully demonstrated the use of calcium carbonate for productivity improvements and physical property enhancement.[1,2,3] One of the key .

However, these biobased and biodegradable polymers typically have mechanical properties that are not on par with the non-biodegradable plastic products they intend to . Among these, calcium carbonate (both natural and synthetic) is the most abundant and affords the possibility of improved surface finishing, control over the . This paper discusses the utilization of HDPE Recycled Plastic Bottle Caps (RPBC) with Calcium Carbonate as potential construction material. Post-consumer plastic bottle . A range of formulations — consisting of high-density polyethylene, surface-coated calcium carbonate, masterbatched carbon black and a stabiliser package — were compared .

The influence of calcium carbonate (CaCO 3) with different polymorphs (calcite and aragonite) and morphologies (granular and rod-like) on mechanical and crystallization properties of . In this paper, high-density polyethylene (HDPE) was compounded with different waste fillers such as silica, kaolin, calcium carbonate, and fly ash with an aim to compare the .

calcium carbonatein plastic feeding

The demands for plastic bottles have expanded beyond their basic container functions. Rising quality and performance requirements necessitate the selection of suitable additives during plastic bottle manufacturing to ensure they better fulfill diverse daily needs. As a versatile additive, calcium carbonate bestows plastic bottles with unique multifaceted applications . This is widely used in plastics industry for many economic benefits. Filler Masterbatch (or Calcium carbonate CaCO3 Filler Masterbatch) manufactured by masterbatch manufacturers is compound of . The manufacture of glass bottles primarily relies on a selection of natural raw materials. The central components include: Silica (SiO2): Often sourced from sand, it is the primary substance, providing structural strength to the glass. Soda Ash (Sodium Carbonate): It acts as a flux to lower the melting point of silica. Limestone (Calcium Carbonate): It is added . For a long time, Calcium Carbonate (CaCO3) is widely used in the plastic industry as an important addictive and filler material. Now let’s discover why Calcium carbonate is being a key player .

Calcium carbonate may be used with a myriad of thermoplastic resins. example, pFor olypropylene compounds are often filled with calcium carbonate to increase rigidity — an important requirement for operations at high temperatures. In polyvinyl chloride (PVC), calcium carbonate is used compounds for to produceflexible1.1 The test methods described in this standard are static laboratory screening tests designed to give a measure of the ability of scale inhibitors to prevent the precipitation of calcium sulfate and calcium carbonate from solution at 71°C (160°F). 1.2 .

The influence of calcium carbonate (CaCO 3 ) with different polymorphs (calcite and aragonite) and morphologies (granular and rod-like) on mechanical and crystallization properties of polypropylene (PP) was investigated. Meanwhile, these CaCO 3 fillers coated with oleic acid were added in different contents to PP. The results indicate that the tensile strength, flexural .All over the structure (Sharma yashasvi,2018). Plastic is water resistant material this can help in avoiding blocks absorbing water that may decrease the blocks strength. Moreover, Calcium Carbonate (CaCO3) has a big role also when it comes in both building materials and construction as an ingredient of cement.Calcium Carbonate Master Batch Production Twin Screw Extruder, find complete details about Calcium Carbonate Master Batch Production Twin Screw Extruder, masterbatch extruder, masterbatch machine, calcium carbonate production line - Haisi Extrusion Equipment . as well as hard plastic recycling, such as PET bottles, TPU wastes, ABS shield, etc .

samples of calcium carbonate. While Sample A is a precipitated calcium carbonate (PCC) with a relatively low bulk density, Sample B is a granular calcium carbonate with a much higher bulk density. The diagram on page 3 shows a schematic representation of the pneumatic conveying system required to transfer the calcium carbonate from a storage binJT Baker® 1294-01 Calcium Carbonate, Powder, BAKER ANALYZED™ ACS Reagent Grade, 500g Poly Bottle Javascript is disabled on your browser. To view this site, you must enable JavaScript or upgrade to a JavaScript-capable browser. In this study, we investigated the use of a natural process called microbial induced calcium carbonate precipitation (MICP) to 'grow' bio-bricks using the urea present in human urine.

We previously showed that the addition of a silane coupling agent effectively modified calcium carbonate and improved its compatibility with PBAT. Compared with neat PBAT/calcium carbonate films, the modified material had better mechanical properties and was more resistant to hydrolysis and photodegradation [32,33]. As mulching films should be . How much calcium carbonate goes into a given bag film depends on application, resin, gauge, color, and, more than anything else, on how the bags are sold–by gauge, weight, or unit count. The increased density of filled film results in increased weight at the same bag thickness and fewer bags for a given weight. Both factors limit filler use.

calcium carbonate in polyolefins

Calcium Carbonate Formula. It is a chemical compound with the chemical formula CaCO 3.; It is a white insoluble powder-like substance which occurs naturally in minerals, chalk, marble, limestone, calcite, shells, pearl, etc.; .

Why do I need a calcium blood test? There are four main reasons why you may need a calcium blood test, including: Your healthcare provider may have ordered routine bloodwork called a basic metabolic panel (BMP) or .

Calcium carbonate (CaCO 3) is an important inorganic mineral in biological and geological systems.Traditionally, it is widely used in plastics, papermaking, ink, building materials, textiles, cosmetics, and food. Over the . Dry the sample at 105° C for 4 hr. On opening the chamber, immediately close the LOD Bottle, transfer it to desiccator and bring it to room temperature. Weigh up to constant weight. Calculation W2 – W1 % Loss on drying = ----- X 100 W2 – W3 Where: W1 = Weight of empty clean and dried LOD Bottle. W2 = Weight of LOD Bottle + sample. III. Calcium carbonate uses in plastic 1. Calcium carbonate filler for packaging products. Filler masterbatch made from CaCO3 and LDPE, LLDPE, MDPE, MPE and HDPE resins can be applied to LDPE, HDPE bag blowing products, helping to improve physical performance and properties. Calcium carbonate resin fillers bring advantages to the end . PP, HDPE, and PET residues were combined with cedar sawdust and a Calcium Carbonate (CaCO 3) . Plastic bottles have been filled with plastic food wrappers [81 . (5 wt%) were subjected to the flexural and compressive stress tests. The samples with a sand: plastic ratio of 0:60 had the highest FS and CS values of 39.08 and 158.06 MPa .

/The study's/ objective was to test the hypothesis that calcium phosphate would better support anabolic bone building than would calcium carbonate. This study was a 12-mo, randomized, positive-comparator, 2-arm, single-blind clinical trial in 211 patients treated with teriparatide who consumed <1000 mg phosphorus/d.

Calcium Carbonate is commonly found in the earth’s crust. It is available in different forms, such as limestone, marble, calcite, and aragonite. The bulk production of Calcium Carbonate occurs by mining or quarrying marble stones. Calcium carbonate can naturally be found in shells from shellfish to snails and eggshells. Manufacturer of antacids containing calcium carbonate. Formulations include calcium carbonate 420 mg, simethicone 80 mg, calcium carbonate 500 mg and calcium carbonate 750 mg. OTC products available also include analgesics, cough, cold and flu formulas, allergy and sinus relief medicines, sleep and alertness aids, laxatives and digestives. A carbon–sulfur by-product material called Blowdown (B) has recently been considered as a possible alternative to calcium carbonate (CaCO3) as a mineral filler. This article studied the impact of acrylonitrile–butadiene–styrene (ABS) polymer on dense-graded (DG) mixtures with two different types of filler: CaCO3 and B-waste, which is an alternative filler. .

show in mg/L calcium as calcium carbonate. This value is the amount of calcium in the sample expressed as CaCO 3. Interferences Interfering substance Interference level Ca > 1.0 mg/L; Mg > 0.25 mg/L For the most accurate calcium test result, run the test again on a diluted sample if the calcium is over 1.0 and the magnesium is over 0.25 mg/L as . These bottles are most commonly used in medicine, particularly to hold injectable medications. Borosilicate: This kind of glass bottle is made from 80% silica and 10% boric acid. The remaining 10% consists of sodium oxide and aluminium oxide. These bottles are 10 times stronger than Type II bottles and are often used for laboratory chemicals.

Assay— Transfer about 200 mg of Calcium Carbonate, previously dried at 200 for 4 hours and accurately weighed, to a 250-mL beaker. Moisten thoroughly with a few mL of water, and add, dropwise, sufficient 3 N hydrochloric acid to dissolve. Add 100 mL of water, 15 mL of 1 N sodium hydroxide, and 300 mg of hydroxy naphthol blue, and titrate with 0.05 M edetate disodium VS .

calcium carbonate feeding system

calcium carbonate feeding problems

Place your bets here! BetMGM Race & Sportsbook is the only spot in Atlantic City .

calcium carbonate loading plastic bottle manufacturing tests|calcium carbonate feeders